Revolutionizing Corrosion Testing with Salt Spray Chamber

- Jan 15, 2025

- | 25

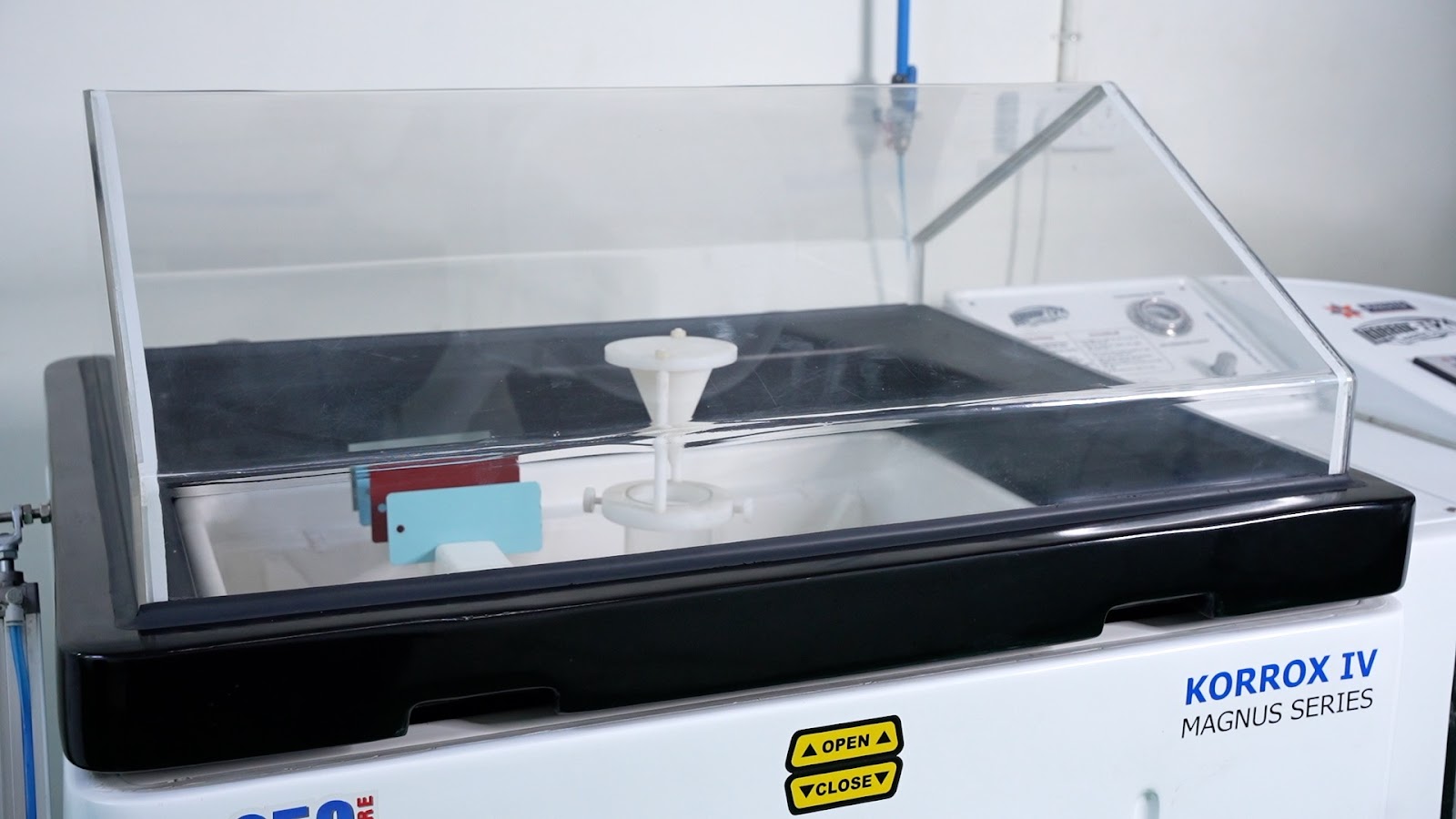

Even today, corrosion persists to be a major problem in many industries. Salt spray testers, or salt fog chambers, are highly important when testing the material for usage in such conditions by measuring its strength with regard to sustaining the corrosive atmosphere. The corrosion tester produces a simulated environment with fast-tracked acceleration of corrosion; therefore, one is sure products made from materials would last a long time without failures.

Salt Spray Chamber Working

The salt fog test chamber is a high-end corrosion testing machine, designed from precise components to achieve trustworthy testing. The key components in it include:

-

Atomizing Nozzle: The saline solution is atomised to produce a fine mist that ensures uniform deposition on the test specimens.

-

Chamber Environment: Heaters and controllers are incorporated to provide a controlled temperature and humidity environment.

-

Solution Reservoir: The saline solution, a 5% NaCl solution, is prepared as per the standards of ASTM B117.

-

Air Saturator: Preliminary heating up of the pressurised air before atomising, which allows for the appropriate formation of salt mist.

Process Operation

In salt spray equipment, the process operation is strictly a balance between chemical and mechanical parameters:

Salt Solution Preparation Using the formula of:

The solutions are prepared accordingly to meet the precise testing standards from ISO 9227 or ASTM B117.

Loading Test Samples: Materials that are placed into racks without overlapped materials such that the exposing of the elements is uniform.

Environment Simulation: The chamber temperature is set at (usually between 35°C to 50°C) and the atomizer starts the salt spray process.

Test Duration: From 24 hours up to 1000 hours or more depending on the intended application of the material and the level of corrosion resistance needed.

Evaluation: After the test, the specimens are examined for surface degradation, pitting, or penetration of corrosion using visual inspection and sophisticated analytical methods.

Why Us?

Why Us?

Presto has been creating leading testing instruments in the manufacturing landscape for more than 4 decades. Our Experience and expertise speak for itself as we are proud nation award winners for quality. Be a part of a family of thousands and take step towards a better future.

Features of Salt Spray Test Apparatus

Automated Control Systems: Microprocessor-based controllers for controlling temperature, humidity, and spray time with high precision.

Data Logging and Remote Monitoring: Real-time tracking and analysis of test parameters with transparency and traceability.

Chambers with inert materials like polypropylene to withstand corrosive environments

Multi-Cycle Capabilities: Simulates complex corrosion conditions by alternating between salt spray, dry, and humid cycles.

Eco-Friendly Design: Low-consumption atomizers and efficient air circulators reduce the cost of operations and environmental effects.

Applications Across Industries

Automotive Sector:- Automotive industries use salt fog chambers to check body panels, fasteners, and coatings of vehicles for their resistance to road salt and other environmental pollutants.

Aerospace Industry:- Salt fog chambers test the corrosion resistance of aircraft components such as aluminium alloys and protective coatings for strict safety standards.

Construction Materials:- Tests on paints, galvanized steel, and concrete reinforcements determine their longevity in harsh environmental conditions.

Advanced Technical Values and Standards of Salt Spray Test Chamber

The Salt Spray Test Chamber follows advanced technical standards, ensuring precise environmental conditions to simulate corrosion.

-

Salt Fog Density: Usually maintained at 1-2 mL/hour per 80 cm².

-

Chamber Capacity: Varies from small (60 litres) to industrial-scale chambers exceeding 1000 litres.

-

Temperature Tolerance: Precise control within ±0.5°C to maintain testing consistency.

-

Pressure Regulation: Atomizing air pressure is kept between 1.0 to 2.0 bar for optimal mist generation.

-

Standard Compliances: ASTM B117, ISO 9227, JIS Z 2371, and other international standards ensure global applicability.

FAQs

FAQs

What is the purpose of running a salt spray test?

A salt spray test is used to assess the corrosion resistance of material and coatings to thus make it suitable for certain environments. The test gives accelerated results to predict the lifespan of the material in real-world conditions.

What Industries can use Salt Spray Chamber in testing?

A salt spray chamber is easily applied to many industries like automotive, aerospace, marine engineering, electronics, and construction in order to measure the corrosion resistance of a particular sample.

Which types of materials can be subjected to testing using a salt spray chamber?

All metals especially steel, aluminum, and copper alloys are checked. Further paints and galvanizing, anodizing all plastics, and composites may be considered.

Selecting the Right Salt Spray Chamber for Your Requirements

There are several considerations in choosing a salt spray chamber. These are as follows:

Testing Standards: It should meet industry-specific standards.

Chamber Size: Select a capacity that accommodates your testing requirements.

Advanced Features: Select features such as programmable controls and multi-environment capabilities for versatile testing.

After-Sales Support: Efficient customer care and maintenance support ensures long-term efficient working.

Salt spray chambers for sale are in abundance for investment, as different industrial needs have various solutions available.

Conclusion

Salt spray testers are a crucial piece of equipment for industries to make their products last longer and be more resilient. With advancements in technology, the salt spray testers give a precise result with higher efficiency. By understanding its working principles and innovative features and by knowing its wide applications, businesses may make informed decisions to protect themselves against the perpetual challenge of corrosion. Whether an automotive, aerospace business or perhaps any other corrosion-susceptible sector, an effective salt spray chamber is that ally in the quest for quality and reliability.

Phone: +91-9210 903 903

Mail: info@prestogroup.com

1.jpg)