Screw Vacuum Pumps: A Complete Guide to Design, Operation, and Industrial Use

Screw vacuum pumps have emerge as vital in a big range of industrial applications because of their potential to operate successfully under both low and high vacuum situations. These pumps are known for their oil-unfastened operation, reliable overall performance, and minimum preservation necessities, making them specially appropriate for approaches requiring contamination-free vacuum environments. As industries preserve to are searching for strength-green and durable solutions, selecting the proper device is usually a result of distinctive collaboration with a relied on industrial products producer that knows software-precise demanding situations.

How Screw Vacuum Pumps Work

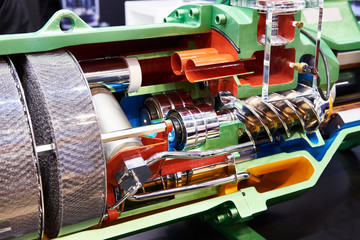

Basic Operating Principle

Screw vacuum pumps perform on a high quality displacement mechanism involving intermeshing screw rotors housed inner a chamber. As the rotors rotate, gas is drawn into the pump, trapped among the screw threads, and compressed closer to the release cease. This design gets rid of the need for internal contact or lubricants in the compression chamber, making the gadget perfect for easy packages.

The absence of oil in the compression quarter distinguishes screw pumps from other technology, lowering the chance of contamination and simplifying downstream filtration.

Dry and Wet Configurations

There are most important styles of screw vacuum pumps dry and wet. Dry screw pumps are designed without any sealing or lubricating fluids in the compression region. Wet variations, then again, use water or any other fluid to assist in sealing and cooling. The preference among these configurations depends at the application’s sensitivity to infection, running temperature range, and cost concerns.

Key Features and Advantages

Oil-Free Operation

One of the most full-size blessings of screw vacuum pumps is their ability to function with out oil in the process chamber. This guarantees easy, uncontaminated output, that's important in industries like pharmaceuticals, meals processing, and electronics production.

High Efficiency and Energy Savings

The rotary movement of the screws and the continuous compression system make a contribution to better energy efficiency. These pumps provide variable pace options, taking into consideration optimized power utilization primarily based on demand. This not handiest reduces operational fees however also aligns with developing electricity conservation desires.

Low Maintenance Requirements

Since the screw rotors do no longer come into direct contact, there's minimum wear and tear. This design minimizes the need for common replacement parts, main to extended provider periods and lower protection prices.

Applications of Screw Vacuum Pumps in Industry

Pharmaceutical and Biotechnology

In cleanroom environments and sterile processing systems, screw vacuum pumps are favored for their hygienic operation. From freeze-drying to solvent recuperation, these pumps meet stringent purity and reliability standards required by way of regulatory bodies.

Chemical and Petrochemical Industries

Screw vacuum pumps handle aggressive vapors, corrosive gases, and flammable materials simply. Their ability to run constantly beneath harsh situations makes them perfect for vacuum distillation, evaporation, and degassing in chemical production.

Food and Beverage Sector

From vacuum packaging to dehydration and distillation, the meals enterprise relies on screw pumps for contaminant-unfastened processing. The oil-free design also prevents taste and aroma contamination, maintaining product integrity.

Electronics and Semiconductor Fabrication

Semiconductor fabrication calls for extremely-easy environments and precise vacuum situations. Screw vacuum pumps meet those desires by means of supplying strong vacuum stages and compatibility with reactive gases used in wafer processing.

Design Considerations for Efficient Operation

Rotor Profile and Geometry

The shape and length of the screw rotors notably impact pump overall performance. Modern designs make use of variable pitch profiles to optimize gasoline go with the flow, lessen electricity consumption, and limit noise. The spacing among rotors and the housing guarantees green compression without contact, keeping the integrity of internal components.

Cooling Systems

Effective thermal control is critical for preserving overall performance and durability. Screw vacuum pumps can be geared up with air or water cooling systems depending on heat load and environmental conditions. Proper cooling prevents overheating and allows for extended operation with out interruption.

Seal Design and Gas Compatibility

In applications handling toxic, corrosive, or explosive gases, deciding on the right sealing fabric is crucial. Mechanical seals, lip seals, and shaft sealing structures are engineered to offer robust containment and save you leaks below varying pressure differentials.

Comparison with Other Vacuum Technologies

Screw Pumps vs. Rotary Vane Pumps

While rotary vane pumps are extensively used for low to medium vacuum applications, they regularly require oil in the procedure chamber and more common protection. Screw vacuum pumps, via assessment, supply oil-free operation, making them suitable for extra traumatic and purifier environments.

Screw Pumps vs. Liquid Ring Pumps

Liquid ring pumps use a rotating liquid ring for compression, which may be less green in phrases of energy utilization and restricted by the sort of manner fluid. Screw pumps keep away from fluid-related demanding situations and supply extra adaptability for diverse gases, together with people with moisture or particulates.

Screw Pumps vs. Scroll and Diaphragm Pumps

Scroll and diaphragm pumps are first rate for small-scale packages requiring compact layout and occasional glide quotes. However, screw pumps outperform them in commercial-scale structures wherein better waft rates, deeper vacuum stages, and chemical compatibility are critical.

Performance Optimization and Troubleshooting

Monitoring System Parameters

To make sure dependable overall performance, crucial parameters inclusive of inlet strain, temperature, and motor load have to be constantly monitored. Modern screw vacuum pumps frequently come prepared with manipulate structures for real-time diagnostics and faraway get admission to.

Identifying Operational Issues

Performance drops may be because of fuel blockages, seal put on, or temperature imbalances. Understanding regular running behavior is prime to early detection. Routine inspections and calibration of sensors make sure constant functionality.

Preventative Maintenance Practices

Scheduled cleansing, lubrication of bearings, and verification of shaft alignment are wellknown practices that save you surprising downtimes. Even with their low-protection layout, these steps assist maintain top efficiency and extend equipment existence.

Environmental and Safety Benefits

Reduced Emissions

Since there are no lubricants inside the gas course, screw vacuum pumps inherently lessen risky organic compound (VOC) emissions. This aligns with environmental policies and helps sustainability tasks in many industries.

Improved Workplace Safety

The quiet operation, minimum vibration, and enclosed compression chamber reduce risks associated with exposure to noise and mechanical failures. Additionally, the usage of inert sealing and cooling options helps limit fireplace hazards in hazardous places.

Technological Advancements in Screw Vacuum Pumps

Smart Monitoring and Automation

With the rise of Industry 4.0, many modern-day screw vacuum pumps are integrated with sensors and statistics analytics systems. These structures offer operators with predictive protection alerts, strength utilization reports, and fault diagnostics, all in actual-time.

Modular and Compact Designs

Engineers are focusing on space-green designs that provide modular configurations. These trends help flexible installation in current procedure layouts while keeping excessive throughput and overall performance.

Energy Recovery Systems

Some advanced models now incorporate strength recuperation capabilities, which includes utilizing compressed gas heat for preheating or technique reuse. These improvements make contributions to reduced basic energy footprints in business settings.

Conclusion

Screw vacuum pumps have established themselves as versatile, high-performance answers for commercial vacuum programs. Their oil-loose, low-preservation layout and adaptability to diverse gases and strategies cause them to an crucial device throughout many sectors. Whether hired in pharmaceuticals, chemical processing, or electronics, these pumps deliver unmatched reliability and efficiency.

By partnering with an skilled industrial products manufacturer, groups can personalize screw vacuum pumps to satisfy particular operational desires. As era advances, these structures keep to conform, riding cleaner, smarter, and greater green vacuum answers for the industries of the next day.